Products

Fluidized Bed Gasifier for Polygeneration

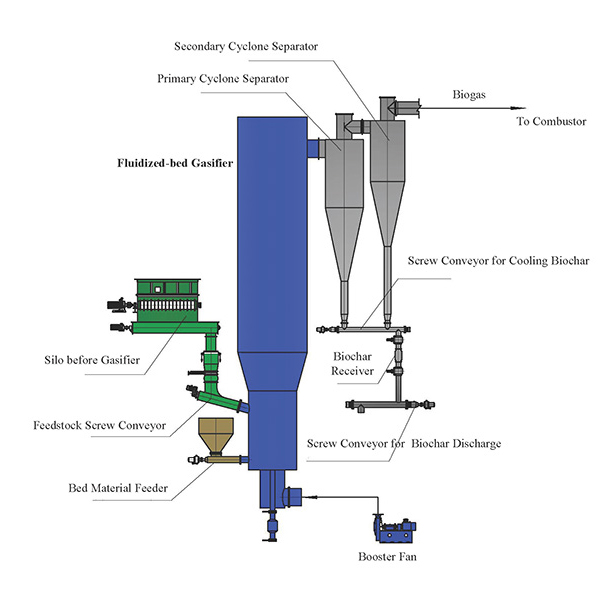

This equipment can be applied to large-scale projects, capable of processing powdered feedstock in the size of below 3cm like sawdust, straw and bamboo scraps, and consuming 40t/h feedstock in maximum for a single equipment, generating both biogas and biochar.

Product Introduction

Introduction on Technical Process

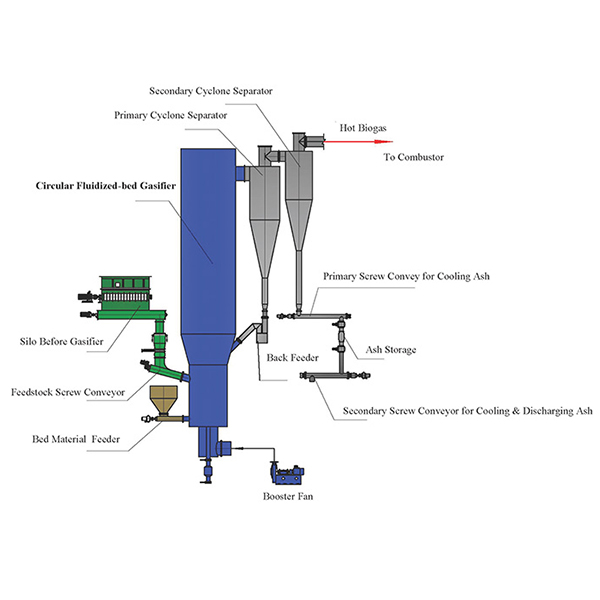

The biomass feedstock is sent into the gasifier continuously throught the feeder system to have pyrolysis and gasification reaction with the small volume of air sent through the air blower at the bottom of gasifier. The energy generated can help maintain the stable reaction within the gasifier and turn the feedstock into biogas and biochar in an efficient way. The biochar is carried outside the gasifier along with the biogas and will be separated and collected through the primary and secondary cyclone separators. Then it will be cooled and collected through the screw conveyor installed at the bottom of the cyclone separator. The biogas will be sent to the combustor for heat supply through the induced draft fan.

Main Parameters

Feedstock process capacity: ≤40t/h

Output Capacity

Max. saturated steam output for single gasifier: 90t/h

Gasifiable Feedstock

straw, sawdust and bamboo scrap, etc; particle size: ≤3cm

Moisture: ≤40%

Conversion Ratio

Feedstock conversion ratiro: ≥90%

Application

Application: alternative to natural gas, coal and other fossil fuels to supply steam, heat and power for energy-using enterprises such as chemical plant, priting and dyeing mill, package plant, wood-working factory, smelting plant and foodstuffs factory; the biochar can be made into high-value products like activated carbon, machine-made carbon, carbon-based fertilizer, thermal insulation material, and capacitor carbon/silicon-carbon black