Products

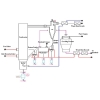

Dual Circulating Fludized Bed Gasifier

This equipment is capable of processing powdered feedstock straw, rice husk, bamboo scrap and sawdust, and consuming 40t/h feedstock in maximum for a single equipment, featuring high efficiency in biogas generation for synthesis of green chemicals.

Product Introduction

Introduction on Technical Process

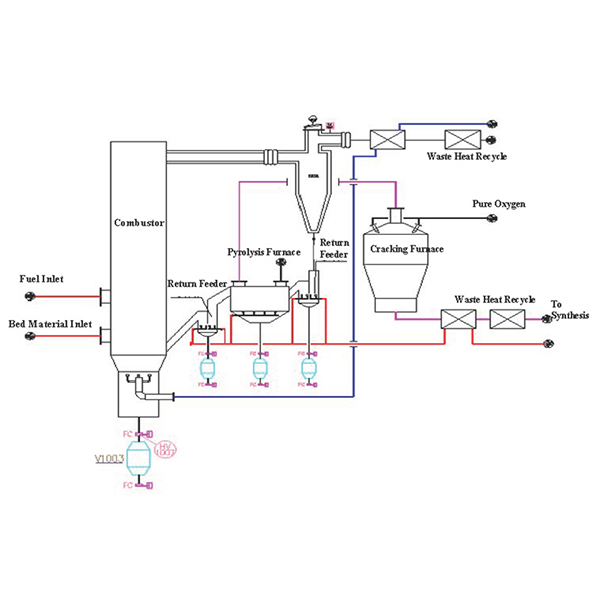

The dual circulating fluidized bed gasifier consists of a combustion furnace and a pyrolysis furnace, and the two beds are coupled together by high-temperature circulating particles. All biomass is added to the pyrolysis bed, and under the heating effect of the high-temperature circulating particles, it is pyrolyzed and gasified with the water vapor added to the gasification bed to produce high-quality synthesis gas. The semi-coke that is not completely gasified enters the combustion furnace through the pyrolysis furnace return feeder for combustion, and the circulating particles heated by the heating circulating particles are sent to the pyrolysis furnace through the combustion furnace return feeder for heating. Since no air is added to the pyrolysis bed, the dilution of the fuel gas by a large amount of nitrogen is avoided, thereby obtaining high-quality synthesis gas. After the circulating particles provide heat, gas-solid separation is carried out at the outlet of the pyrolysis furnace to re-participate in the circulation, which does not affect the quality of the fuel gas. High-quality synthesis gas is produced under normal pressure and air conditions. The high-quality synthesis gas undergoes an incomplete combustion reaction with pure oxygen in the tar cracking unit to achieve the cracking of tar and macromolecular hydrocarbons. The gas from the tar cracking unit is recovered through waste heat recovery by gas preheaters, steam heat exchangers, waste heat boilers and other equipment, and then enters the gas cabinet after gas dust removal and gas pressurization. The treated biomass gas is used to extract hydrogen or for chemical synthesis.

Main Parameters

Feedstock process capacity: ≤40t/h

Output Capacity

The biogas generated can be used for chemical synthesis. The biogas produced by a single gasifier can synthesize about 6.25t biomethanol per hour.

Gasifiable Feedstock

Straw, rice husk, bamboo scrap and sawdust, etc.

Moisture: ≤40%

Conversion Ratio

Effective gas content: ≥40%

Application

Application: extraction of hydrogen from the biogas or synthesis of biomethanol and aviation kerosene for shipping and aviation industries.