Products

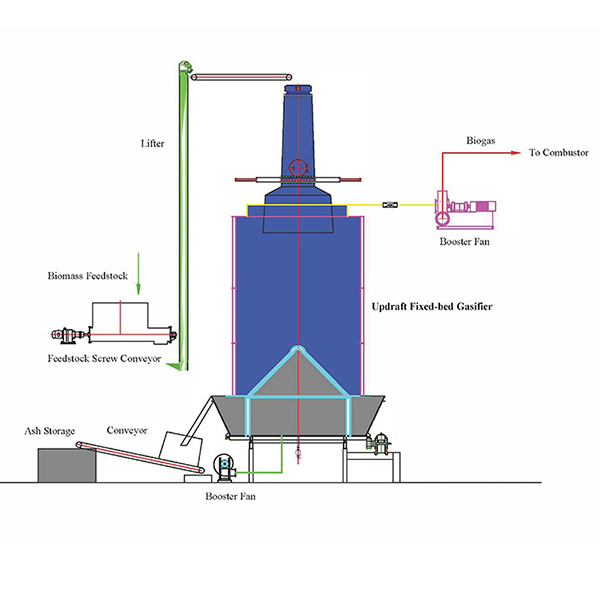

High-efficient Fixed Bed Gasifier

This equipment is capable of processing bark, film faced plywood, straw briquette, wood and bamboo chips in the size of 3~8cm, and consuming 10t/h feedstock in maximum for a single equipment, featuring high efficiency in biogas generation.

Product Introduction

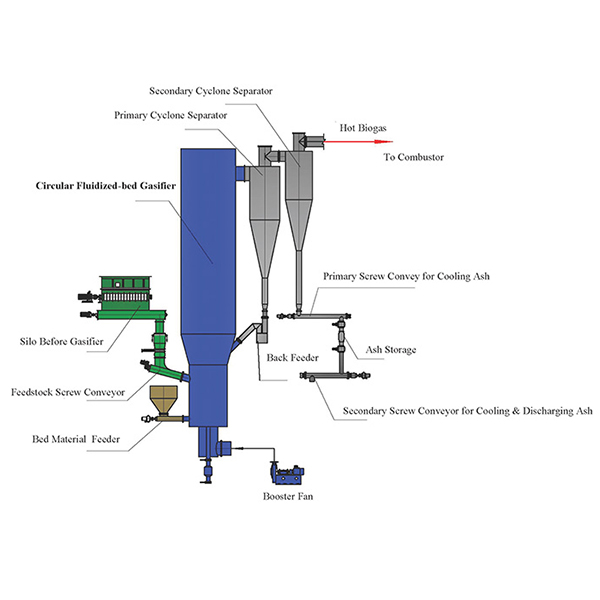

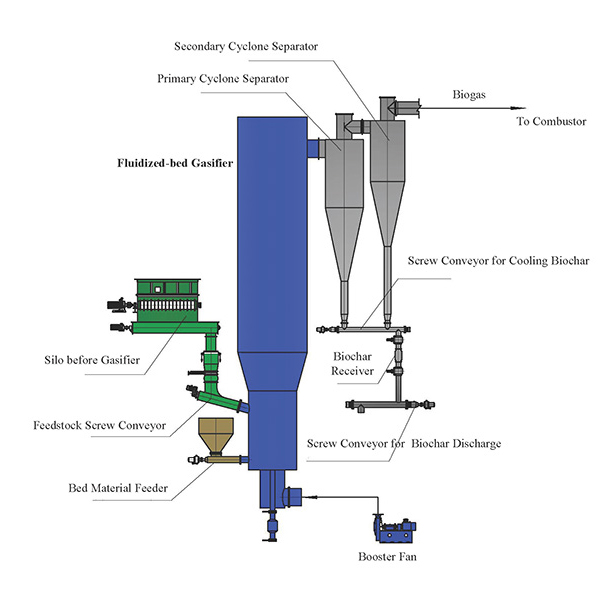

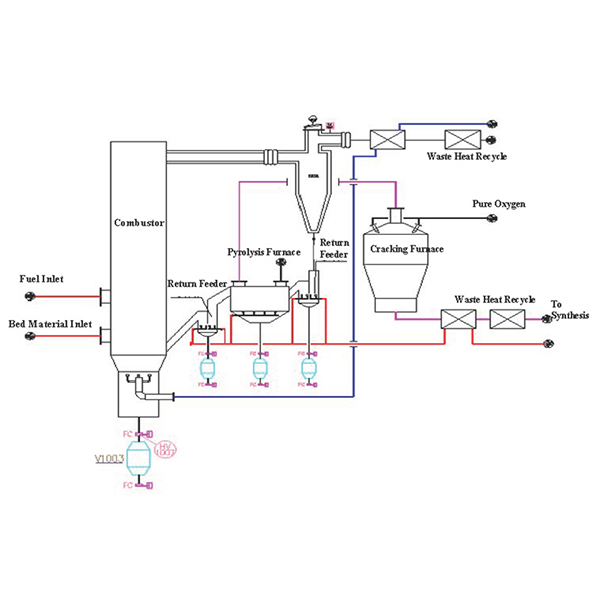

Introduction on Technical Process

The biomass feedstock is sent to the gaisfier intermittently through the feeder system to have pyrolysis and gasification reaction with the air enterting from the bottom. The energy generated can help maintain the stable reaction within the gasifier and turn the feedstock into biogas and biochar in an efficient way. The biogas will be sent from the top of the gasifier to the combustor for heat supply, while the biomass ash will be sent to the bottom ash bucket for cooling through the tower-type grate and dicharged outside the gasifier.

Main Parameters

Feedstock process capacity: ≤10t/h;

Biogas output: ≤18000Nm3/h

Output Capacity

Max. saturated steam output for single gasifier: 25t/h

Gasifiable Feedstock

Bark, film faced plywood, straw briquette, wood and bamboo chips, etc; particle size: 3-8cm

Moisture: ≤40%

Conversion Ratio

Gasification efficiency: ≥80%

Application

Application: alternative to natural gas, coal and other fossil fuels to supply steam, heat and power for energy-using enterprises such as chemical plant, priting and dyeing mill, package plant, wood-working factory, smelting plant and foodstuffs factory; the biochar can be made into high-value products like activated carbon, machine-made carbon, carbon-based fertilizer, thermal insulation material, and capacitor carbon/silicon-carbon black