Off-grid Power Plant: Biomass Gasification for Power Generation: Benefits & Providers

Off-grid Power Plant: Biomass Gasification for Sustainable Power Generation

Biomass gasification turns organic materials into clean energy. Utility companies and rural projects use this technology for reliable electricity. The process is efficient and works with many types of biomass. This article explains how it works and why it matters.

How Biomass Gasification Works

Biomass gasification happens in several steps:

- Feedstock preparation: Biomass is cut into small pieces (normally under 10cm) and dried (moisture below 40%)

- Thermal breakdown: Heat converts biomass into gas at high temperatures

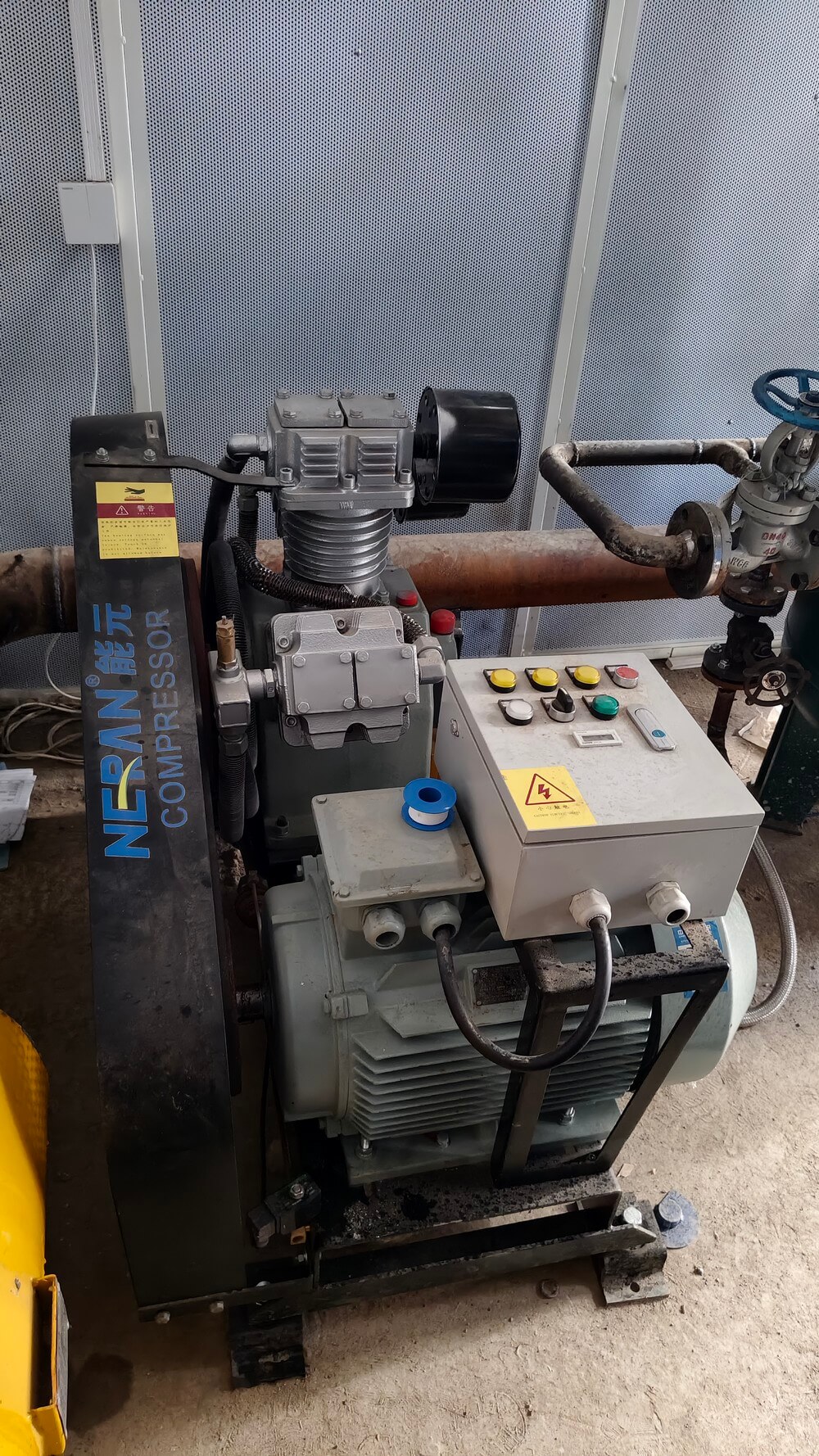

- Gas cleaning: The gas is filtered to remove impurities

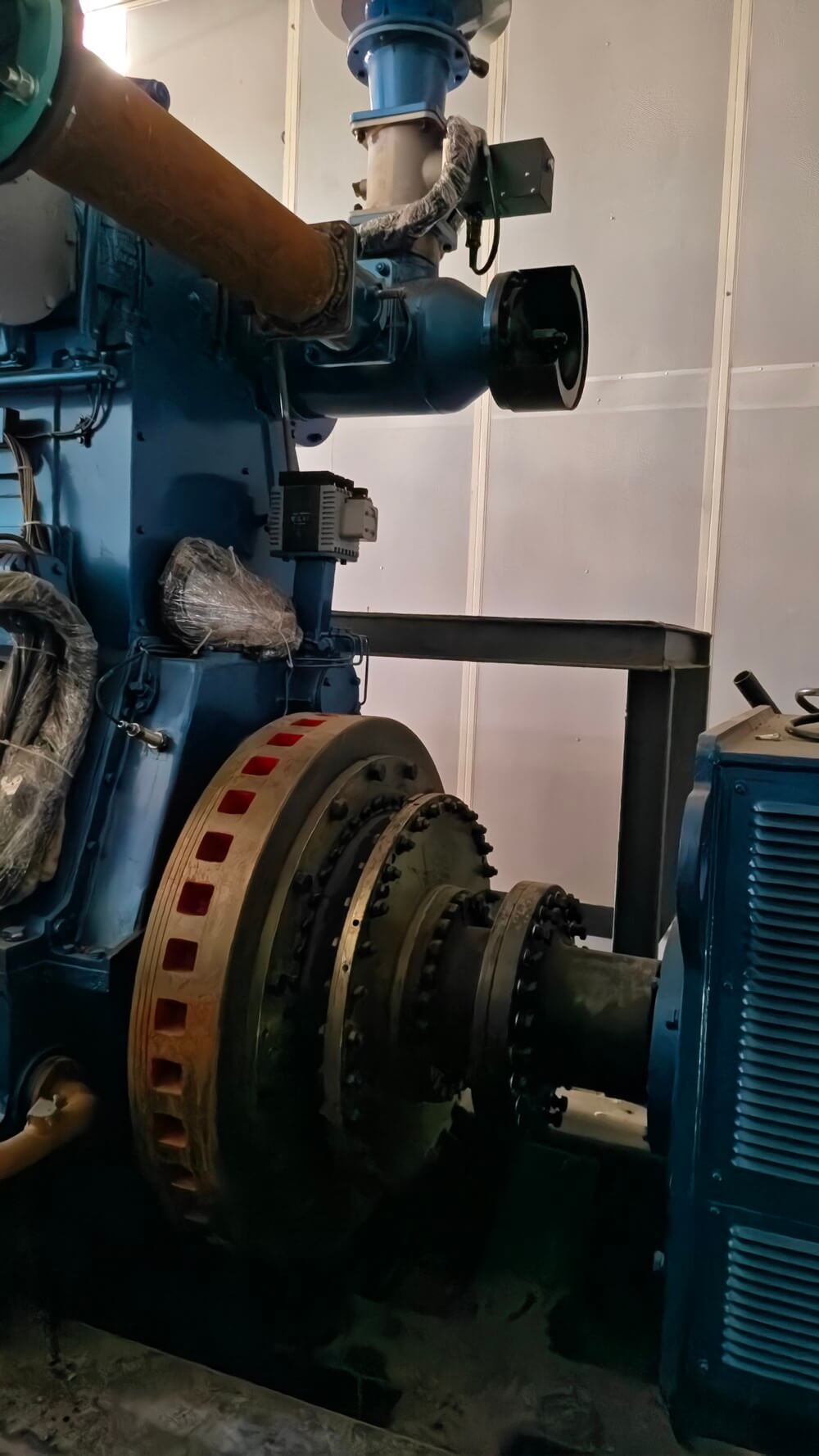

- Power generation: Clean gas fuels engines or turbines to make electricity

The whole process works without complete burning, which makes it cleaner than traditional methods.

Key Benefits for Power Generation

Biomass gasification offers important advantages:

- Higher efficiency: Converts more biomass energy into electricity

- Fuel flexibility: Works with crops, wood, and agricultural waste

- Clean energy: Produces less pollution than burning fossil fuels

- Local solutions: Can power small communities using nearby resources, independent from national grid system

Technology Providers and Solutions

Different systems are available for various needs:

- Micro off-grid systems for villages (100kW-5MW)

- Large systems for utilities (5-50MW)

- Mobile units for emergency power

- Combined systems that work with solar power

Modern systems include automatic controls and cleaning technology.

Economic Considerations

Biomass gasification makes financial sense when:

- Fuel sources are nearby and cheap

- Diesel costs are high in remote areas

- Projects run for several years

- Maintenance teams are trained

Biomass Gasification for Power Generation: How It Works and Why It Matters

Why Choose Gasification Over Other Methods?

Better EfficiencyGasification makes 50% electricity from biomass. Burning directly only gives 20-30%.

Works With Many FuelsRice husks, coconut shells, and wood waste all work. Different materials have different energy values:

- Rice husks: 18MJ/kg

- Coconut shells: 20MJ/kg

It produces 90% less smoke than open fires. The process also makes useful byproducts like biochar for farms.

Costs and Savings

Setup CostsBuilding a system costs $1,500-$4,000 per kW. A 1MW plant might cost $3 million.

Running CostsBiomass fuel makes up 30-60% of expenses. Good planning keeps costs down.

Good InvestmentMany projects pay for themselves in 4-7 years. A rice mill in the Philippines earns 25% yearly profit using its waste.

Challenges to Know About

Getting Enough BiomassPlants need steady fuel supply. Biomass shouldn't travel more than 50km to stay cheap.

Keeping It DryWet biomass doesn't work well. Covered storage or pre-drying solves this.

Finding Skilled WorkersStaff need training to run gasifiers safely and fix problems.

What's Next for This Technology?

- New methods to make even cleaner gas

- Systems that capture carbon for extra climate benefits

- Computer controls to optimize performance

- Growing use in Asia and Africa