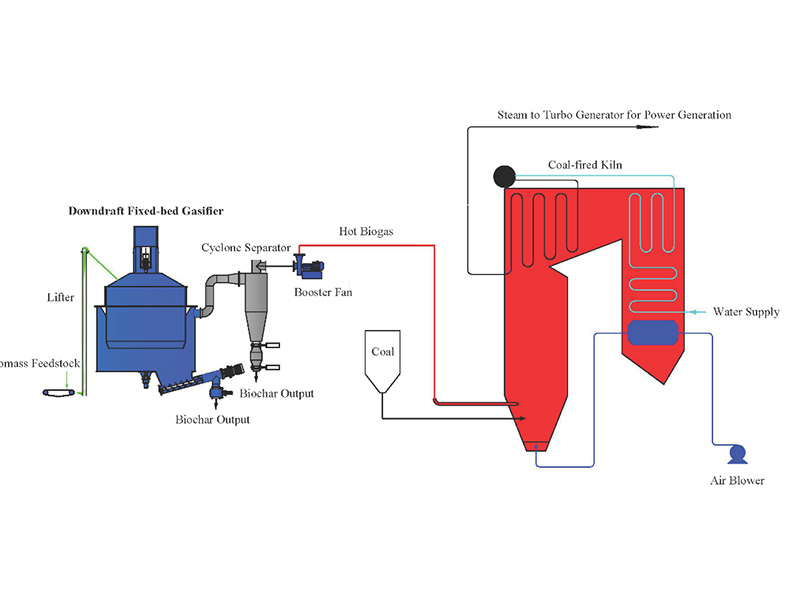

Biomass Gasification Blending with Coal-fired Power Plant for Power Generation

The Biomass Gasification Blending with Coal-fired Power Plant for Power Generation The biogas is sent into the coal-fired boiler to co-generate power at scale by taking advantage of the configuration of the large power station in a highly efficient way.

Feedstock: rice husk, straw, sawdust, bamboo scrape, etc.

Product: electricity

Technological Highlights

The efficiency of mixed-fuel power generation: 32~37% > efficiency of power generation through direct combustion of biomass: 22-27%;

The corrosion to the surface of the boiler for power station by the biomass can be avoided as it is collected before entering the boiler, thus lowering the maintenance cost;

The biogas can reach the temperature of more than 400℃, ensuring high heat efficiency of overall system, and no tar and sewage.

The biomass gasifier is independent from the coal-fired power plant, allowing no influence of the fluctuation of seasonal biomass yield on the continuous stable power generation.

Parameters of Operation

|

No. |

Feedstock |

Gas output efficiency |

Gas calorific value |

Feedstock consumption of unit power generation |

|

1 |

Sawdust/bamboo scrap |

2.5Nm3/kg |

1100~1200kcal/Nm3 |

0.7kg/kW.h |

|

2 |

Straw |

2.2 Nm3/kg |

1050~1150kcal/Nm3 |

0.8kg/kW.h |