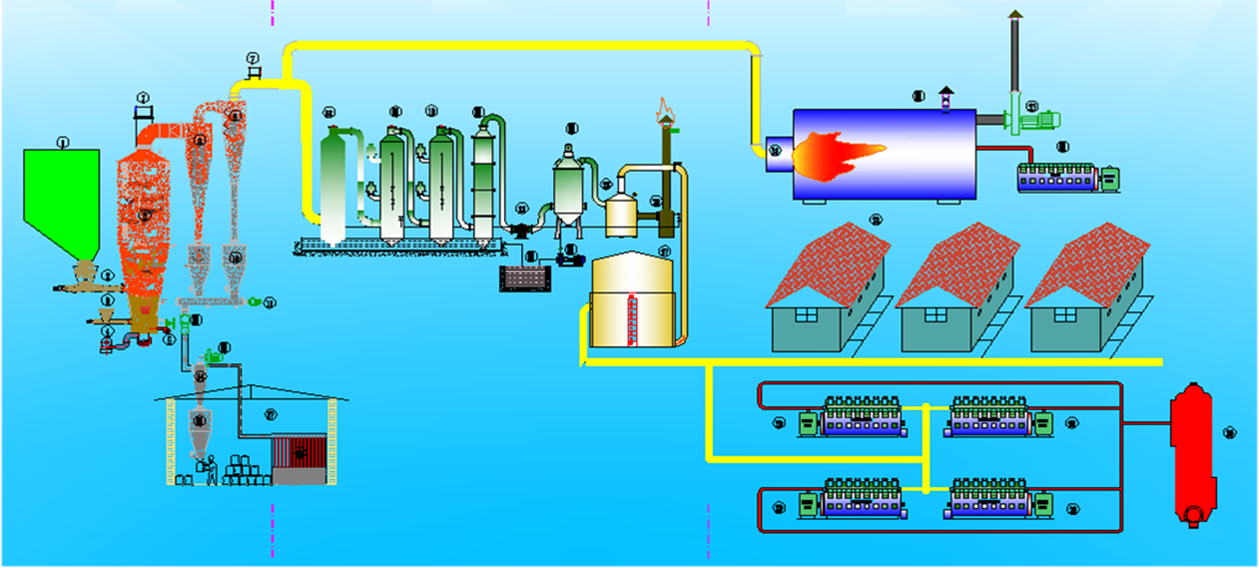

Fluidized Bed Gasifier Power Plant for Poly-generation

Feedstock:

sawdust, bamboo scraps, straw, etc.

Products of Poly-generation

|

No. |

Product |

Description |

Remark |

|

|

1 |

Electricity |

The biogas after being cooled and purified, is

sent into the internal combustion engine generator set or to the steam boiler

to generate steam for power generation through turbine generator. |

|

|

|

2 |

Biochar |

Wood/bamboo charcoal |

Carbon content: 80~85%; Application: production of activated carbon or

machine-made carbon |

|

|

Fruit shell charcoal |

Carbon content: 80~85%; Application: production of high-quality activated

carbon |

|

||

|

Straw charcoal |

Carbon content: 45~50%; Application: production of carbon-based compound

fertilizer |

|

||

|

3 |

Extract |

During the cooling and purify, the biomass

extract in the biogas will dissolved in the circulating water. As the system

runs, its concentration increases. It can be sold to foliage fertilizer plant

when it reaches a certain concentration degree. |

|

|

|

4 |

Heat |

The biogas is sent into the boiler or kiln for

combustion to generate steam or to heat the kiln. The tail gas temperature of

the internal combustion engine generator is around 550℃, which can recycled

to generate heat or hot water, and to dry or cool the material. |

|

|

|

5 |

Biogas |

The biogas after cooling and purification, can be

for household use. |

|

|